Phase Two began in December of 2012 with a mud brick building technique workshop, organization of the onsite team, material acquisition and other details. A significant amount of time was devoted to meetings with the community to address local concerns and to have user input on design changes.

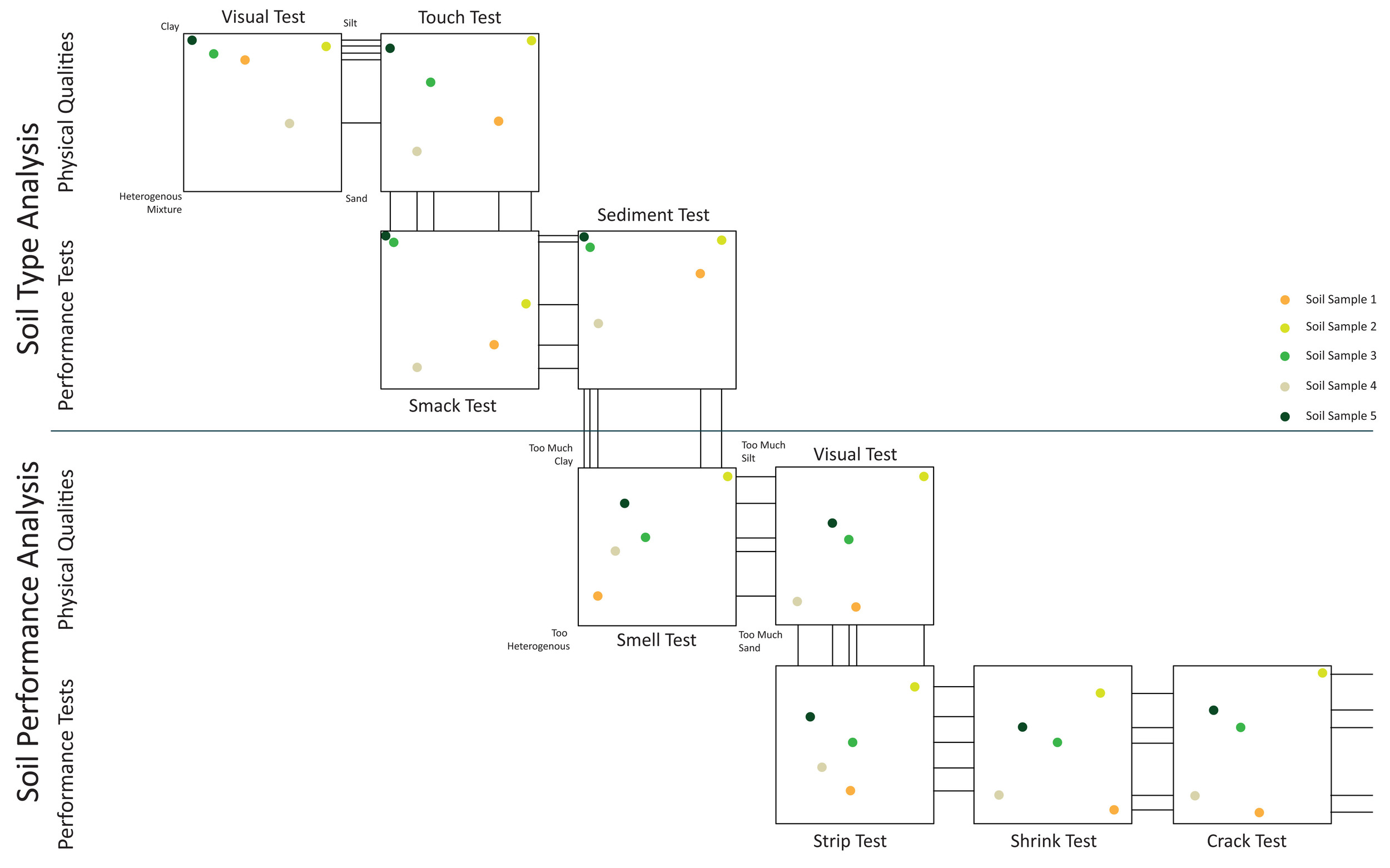

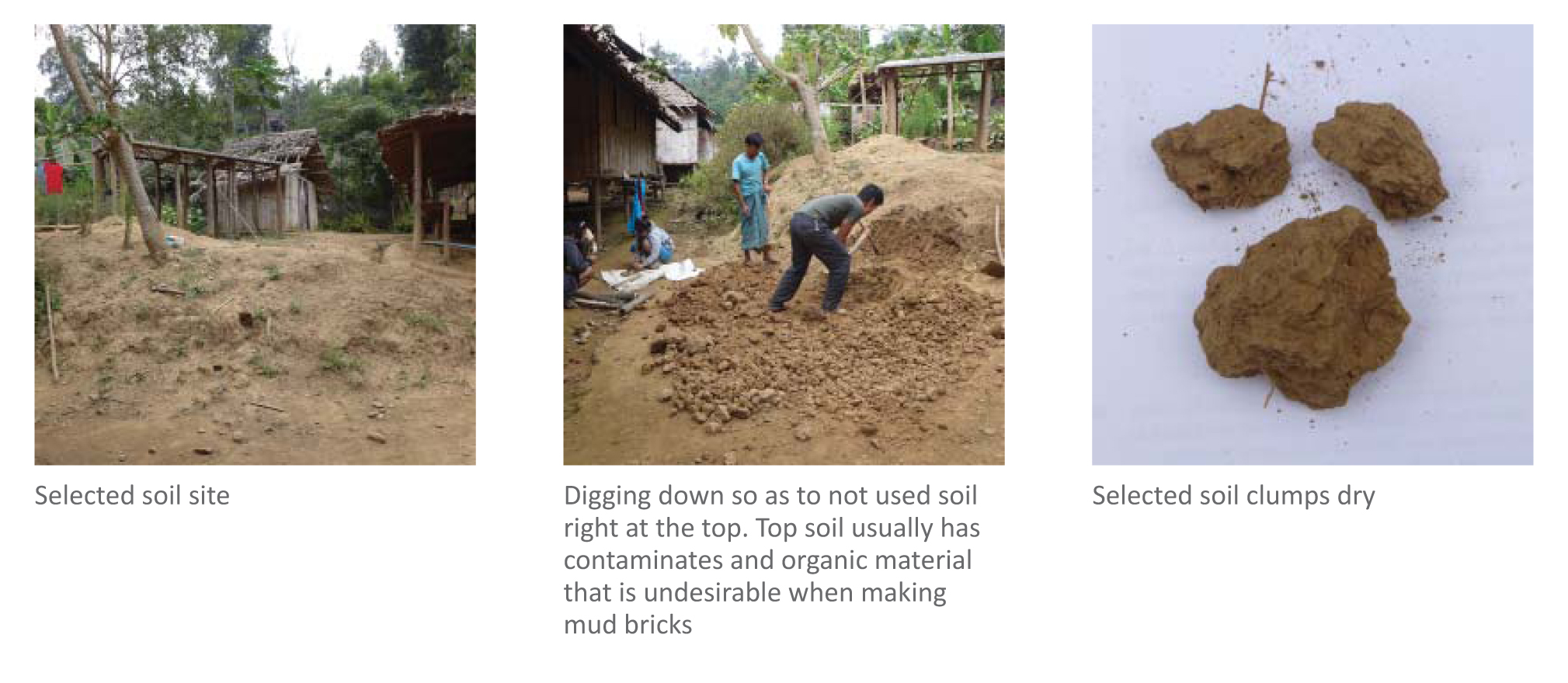

Prior to the mud brick building technique workshop it was important to gather my own information about the soil conditions so that I could know which soil was best to use in the mud bricks. Since it would not be possible to bring in dirt from the mud bricks it was important to do some quick tests on the local dirt to see which was best suited. In general two categories of tests were performed: soil type analysis tests and soild eprformance analysis tests. Soil types generall range from clay to sand with a silt and hetergeneous mixtured coming in between them. Sandy soil is unusable for mud bricks without the addition of clay. Silt with a high clay content can be used and heterogenous mixtures can be used, but are not preferred especially when the contents of the mixture are unknown. Clay soil is the best for mud brick making, but in its most pure form can sometimes dry and crack, so additions of silt and tensile fiberious materials are neccessary. The soil type analysis test were to help determine which of the five sites tested had the best soil for mud brick making. The soil performance analysis tests were then conducted to see how each soil sample behaved. From all the soil samples collected Soil Sample 3 was used since it had a high clay ratio and performed the best in the soil performance analysis tests.

These simple on site tests were taught to those participants during the mud brick making work shop so that they could be empowered to select soil when making their own mud bricks.

Aggregate diagram of the tests performed on the 5 potentional soil samples from the site vaccinity to help determine the utlimate choice for soil use in mud bricks